Proactive Maintenance of Steam Power Plants: How Scheduled Field Services Improve Reliability

Introduction: The Case for Proactive Maintenance

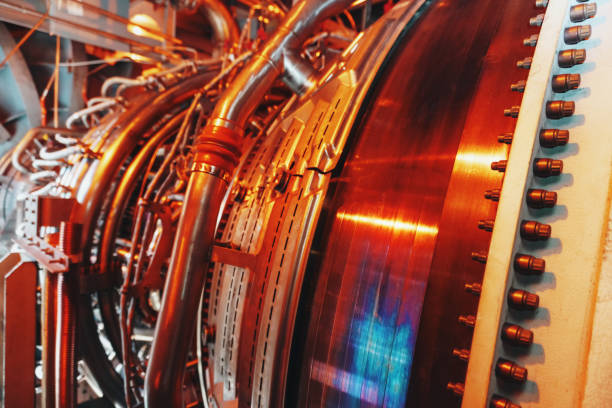

In the world of power generation, reliability and efficiency are paramount. Steam power plants—whether operating as part of base-load or peaking generation—depend on precise performance across turbines, boilers, and auxiliary systems. Yet, even minor deviations caused by wear, misalignment, or debris buildup can lead to major efficiency losses or unexpected downtime.

That’s where proactive maintenance of steam power plants becomes essential. Through scheduled inspections, cleaning, alignment, and lubrication performed by skilled field service teams, operators can identify small issues before they escalate—ensuring consistent output, lower operational costs, and an extended equipment lifecycle.

Understanding the Role of Field Services in Steam Power Plant Maintenance

A steam power plant is a complex ecosystem of rotating machinery, pressure systems, and control equipment. Over time, thermal cycling, vibration, and material fatigue take a toll on components. Field services bridge the gap between continuous operation and optimal performance by delivering targeted, on-site support designed to maintain and restore system integrity.

Typical maintenance of steam power plant operations include:

- Routine inspections of turbines, boilers, condensers, and piping systems

- Cleaning of critical heat exchange surfaces to remove scaling and deposits

- Alignment checks for rotating equipment to minimize vibration and wear

- Lubrication services ensuring proper mechanical efficiency and heat management

Each task is part of a broader preventive strategy—keeping the plant running smoothly while reducing the likelihood of forced outages or costly repairs.

Why Proactive Maintenance Matters More Than Ever

Today’s utilities are under mounting pressure to deliver uninterrupted power while managing tight budgets and aging infrastructure. Proactive maintenance provides a way to achieve these goals simultaneously.

Here’s how it drives long-term value:

1. Reduced Unplanned Outages

Unexpected equipment failures are among the costliest challenges in power generation. A single unplanned outage can cost millions in lost production and emergency repairs.

Scheduled maintenance interventions allow technicians to detect early warning signs—such as bearing wear, steam leaks, or misalignment—before they evolve into major issues.

2. Improved Operational Efficiency

Contaminants, corrosion, and component wear can significantly degrade plant performance. Regular cleaning and calibration restore system efficiency, improving thermal performance and reducing specific fuel consumption. For example, proper lubrication reduces mechanical losses, while accurate alignment helps minimize vibration and energy waste.

3. Extended Equipment Lifespan

Every rotating component—from the turbine rotor to the feedwater pump—has a finite life. Proactive maintenance extends that lifespan by preventing cumulative damage. Inspections that identify cracks, erosion, or pitting allow timely part refurbishment or replacement, helping avoid catastrophic failures.

4. Enhanced Safety and Compliance

Steam systems operate under high pressure and temperature, which makes safety paramount. Regular maintenance ensures that pressure vessels, valves, and piping remain compliant with safety standards and regulations. Field technicians also verify that protective devices—such as safety valves and monitoring instruments—function properly, minimizing operational risks.

See also: How Blockchain Technology Is Revolutionizing Finance

Core Maintenance Interventions That Drive Reliability

To truly improve reliability, maintenance of steam power plants must address both mechanical and thermal integrity. Below are the most impactful service activities:

1. Turbine and Generator Inspections

Turbines form the heart of the power plant. Over time, blades may erode, seals can degrade, and bearings can wear. Scheduled borescope inspections and rotor balancing performed by experienced field engineers ensure that turbines continue operating at peak performance.

2. Boiler and Heat Exchanger Cleaning

Scaling and fouling on boiler tubes and heat exchanger surfaces reduce heat transfer efficiency. Regular cleaning—through mechanical, chemical, or high-pressure water methods—improves thermal output and reduces fuel consumption.

3. Shaft Alignment and Vibration Analysis

Even slight misalignment in rotating components can create excessive vibration, accelerating bearing and coupling wear. Precision laser alignment and vibration diagnostics correct these issues early, preserving both efficiency and equipment health.

4. Lubrication and Oil System Management

Proper lubrication is essential to prevent friction, overheating, and mechanical damage. Field services include oil sampling, filtration, and replenishment to ensure clean, high-quality lubrication throughout operation.

5. Valve and Seal Maintenance

Leaking valves and seals contribute to steam losses, pressure drops, and safety risks. Scheduled maintenance ensures that valve seats, gaskets, and seals remain tight and efficient—improving overall plant performance.

The ROI of Scheduled Maintenance: Numbers That Matter

While proactive maintenance requires upfront investment, its return on investment (ROI) is undeniable. Plants that implement consistent, data-driven maintenance schedules typically experience:

- 30–40% reduction in unplanned outages

- 10–15% improvement in overall efficiency

- 20–25% longer component life cycles

- Significant O&M cost savings through fewer emergency repairs

For example, a 250-MW steam plant that performs consistent field maintenance on its turbine and boiler systems can save hundreds of thousands annually in avoided downtime and reduced heat-rate penalties.

By engaging specialized partners like Allied Power Group, plants also benefit from rapid response times, expert diagnostics, and advanced repair capabilities that further enhance ROI.

Field Service Expertise: The Allied Power Group Advantage

At Allied Power Group (APG), field service is more than just routine maintenance—it’s a reliability partnership. With decades of experience across steam and gas turbine platforms, APG’s field teams combine deep technical knowledge with precision tooling and advanced diagnostics to maximize uptime and performance.

Our field service portfolio includes:

- Comprehensive outage planning and management

- On-site inspections and repairs for turbines, generators, and auxiliary systems

- Precision alignment, balancing, and machining

- Component refurbishment and replacement

- Turnkey solutions for major and minor outages

By integrating these services into your maintenance program, APG helps ensure that your steam power plant continues to operate safely, efficiently, and profitably.

Building a Culture of Reliability Through Proactive Maintenance

Reliability isn’t achieved by chance—it’s the result of consistent, informed action. By investing in proactive maintenance, plant operators shift from a reactive, repair-driven model to a performance-driven one. This transformation leads to predictable operations, stable output, and greater profitability.

Key steps to build this reliability culture include:

- Establishing predictive maintenance schedules aligned with equipment age and operating conditions

- Conducting regular performance audits to identify hidden inefficiencies

- Partnering with experienced field service providers for technical expertise and outage execution

- Documenting maintenance activities for continuous improvement and regulatory compliance

Conclusion: Reliability Begins with Maintenance

The maintenance of steam power plants is not merely a compliance requirement—it’s a strategic investment in reliability, safety, and long-term value. With the right maintenance practices and field service support, plant operators can significantly reduce downtime, extend equipment life, and optimize heat-rate performance.

Partnering with industry leaders like Allied Power Group ensures every aspect of plant health—from turbine balance to valve sealing—is expertly managed. In today’s demanding power market, proactive maintenance isn’t optional—it’s the foundation for sustainable performance.