Tips for Choosing Advanced PCB Solutions for Industry

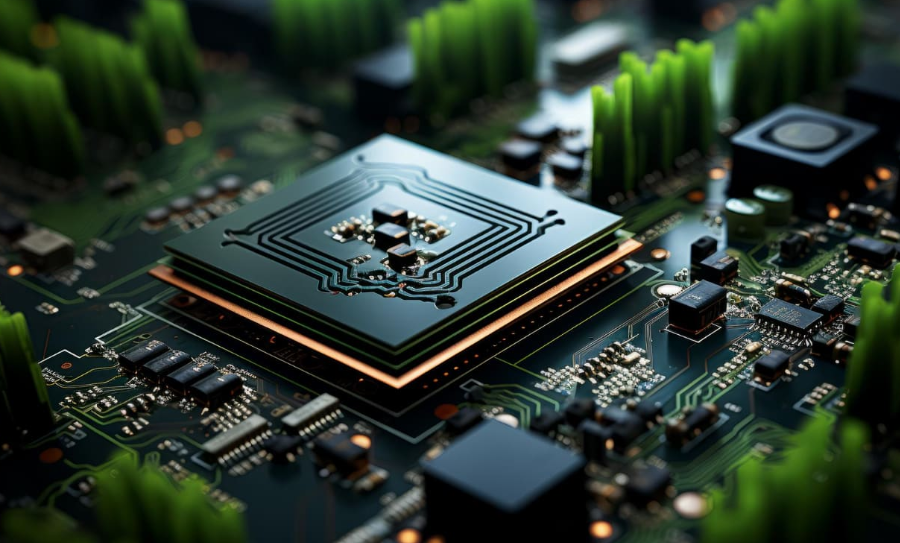

In the rapidly evolving world of electronics, the design and manufacturing of printed circuit boards (PCBs) have become more sophisticated than ever. PCBs form the backbone of electronic devices, connecting components to ensure efficient functionality. For industries like telecommunications, robotics, and industrial automation, selecting the right PCB solutions is critical for achieving high performance and reliability. Businesses can rely on industrial automation PCB assembly services from expert manufacturers to ensure precision and quality in their electronics systems.

Understanding PCB Fabrication and Assembly

Printed circuit boards are the foundation of electronic systems. PCB fabrication refers to the process of designing and producing the physical board, while PCB assembly involves mounting electronic components onto the board to create a fully functional system. Both stages require precision and technical expertise to ensure performance, durability, and compliance with industry standards.

For businesses in industrial sectors, relying on experienced PCB manufacturers can make a significant difference. These manufacturers provide custom PCB solutions, including rigid, flexible, and high-frequency boards, which are essential for modern electronics applications.

Key Considerations When Choosing PCB Solutions

When selecting PCB solutions for industrial or high-tech applications, several factors need to be considered:

1. Industry Requirements and Standards

Different industries have unique technical requirements. For example, telecommunications often require high-frequency PCBs to support fast signal transmission, while robotics applications may demand rigid-flex PCBs for compact and complex designs. Ensuring the PCB complies with industry standards and certifications is crucial for long-term reliability.

2. Material Selection

The choice of substrate material impacts the board’s thermal resistance, durability, and signal integrity. Advanced PCB solutions often use FR-4, polyimide, or specialized high-frequency laminates depending on the application. For demanding environments, such as industrial automation, high-temperature and chemically resistant materials are preferred.

3. Layer Complexity

Modern electronics often require multi-layer PCBs to accommodate complex circuitry within a compact footprint. Multi-layer PCBs improve performance, reduce electromagnetic interference (EMI), and allow integration of sophisticated features, making them suitable for telecommunications and robotics systems.

4. Advanced PCB Types

Some of the most advanced PCB solutions include:

Rigid-Flex PCBs: These combine rigid and flexible substrates, allowing 3D configurations and reducing space constraints. They are ideal for robotics and wearable electronics.

High-Frequency PCBs: Designed for fast signal transmission, these are essential for telecommunications equipment and high-speed data processing.

Heavy Copper PCBs: Useful for industrial automation applications where higher current loads are required.

Selecting the right PCB type can enhance performance, reliability, and longevity of the final product.

See also: How Blockchain Technology Is Revolutionizing Finance

The Importance of Technical Expertise

Working with a manufacturer that offers technical expertise in PCB assembly ensures that complex designs are executed accurately. Experienced manufacturers provide services such as surface-mount technology (SMT), through-hole assembly, and mixed-technology solutions, catering to both prototype and mass production needs.

Applications in Industrial Automation

Industrial automation relies heavily on PCBs for controlling machinery, robotics, and communication systems. Key applications include:

Robotics Control Systems: PCBs enable precise movement control, sensor integration, and communication between robotic modules.

Programmable Logic Controllers (PLCs): High-reliability PCBs ensure smooth operation in factory automation and process control.

Industrial IoT Devices: Advanced PCBs support smart sensors and connectivity for data-driven automation solutions.

Choosing robust and high-quality PCBs minimizes downtime, reduces maintenance costs, and improves overall operational efficiency in industrial settings.

Applications in Telecommunications

Telecommunications require PCBs capable of handling high-speed signals with minimal interference. Some applications include:

5G Equipment: High-frequency PCBs are essential for managing rapid data transfer and maintaining signal integrity.

Networking Devices: Routers, switches, and modems rely on multi-layer PCBs for compact, efficient designs.

Satellite Communications: Rigorous PCB standards are necessary to withstand extreme conditions in aerospace applications.

By leveraging advanced PCB solutions, companies can ensure consistent performance and reliability in demanding telecom environments.

Applications in Robotics

Robotics systems demand flexible, compact, and durable PCBs to accommodate complex designs and dynamic movements. Applications include:

Industrial Robots: Rigid-flex PCBs allow tight integration of multiple control circuits in small spaces.

Autonomous Vehicles: High-frequency PCBs support sensors, cameras, and communication modules.

Medical Robots: Precision PCBs enable accurate control and monitoring in healthcare robotics.

The choice of PCB technology directly impacts a robot’s efficiency, accuracy, and operational lifespan.

Choosing the Right Manufacturer

Selecting the right PCB manufacturer is just as important as choosing the PCB type. Key considerations include:

Experience in Advanced PCB Solutions: Look for manufacturers offering rigid-flex, high-frequency, and multi-layer PCB expertise.

Quality Assurance: ISO certifications, testing protocols, and stringent quality control are essential.

Custom Solutions: The ability to produce tailored PCBs to meet specific industry requirements.

Support for Prototyping and Mass Production: Flexible production capabilities ensure smooth scaling from design to full-scale deployment.

Global Well PCBA is a leading manufacturer that provides industrial automation PCB assembly solutions, combining technical expertise with advanced manufacturing capabilities. Their services cater to a wide range of industries, ensuring high-quality, reliable PCBs for complex electronic systems.

Future Trends in PCB Technology

The PCB industry is evolving rapidly, with emerging trends including:

Miniaturization: Smaller, more compact PCBs for wearable devices and portable electronics.

Embedded Components: Integration of passive and active components directly into the PCB to save space.

Sustainable Materials: Use of eco-friendly and recyclable materials to reduce environmental impact.

High-Speed and High-Frequency Designs: Continued demand for telecom and data-intensive applications.

Staying informed about these trends helps businesses adopt innovative PCB solutions and maintain a competitive edge.

Conclusion

Advanced PCB solutions are critical for modern electronics applications, particularly in industrial automation, telecommunications, and robotics. Choosing the right PCB type, materials, and manufacturer ensures optimal performance, durability, and reliability. By leveraging technical expertise from experienced manufacturers like Global Well PCBA, businesses can achieve high-quality PCB assembly and fabrication tailored to their specific industry needs.

For industries seeking precision, innovation, and reliability, investing in advanced PCB solutions is not just a technical choice—it’s a strategic advantage.